SmartSolo Scientific data-acquisition (DAQ) systems have versatile capabilities that make them ideal for structural health monitoring in a wide range of applications, including simple beam-fatigue, structural mechanics research, and continuous monitoring of large, complex structures. Each system can measure a variety of sensor types, including bonded foil strain gauges, accelerometers, displacement sensors, tiltmeters, and temperature sensors.

To see how our systems meet your application needs, review our case studies »

Data Acquisition (DAQ) Systems for Structural Monitoring and Control

The versatility of our node DAQ systems allows them to be customized for each application.

Nodal Design

The nodal architecture of our M1000 system allows each measurement node to independently connect to a PC or DAQ. As an independent node, the real-time measurements can be displayed directly on the PC. One or more measurement node can be connected to the M1000 DAQ to create the perfect networked configuration for each application. When connected, they form a time-synchronized, distributed DAQ system.

Distributed Networks and Synchronization

Multiple M1000 measurement nodes can be distributed throughout the structure. Each node is connected to a central M1000 DAQ. This networking capability decreases the quantity and lengths of the sensor cables between the sensors and the M1000 DAQ. Fewer sensor cables reduce cost, improves system simplification, and lessens the risk of signal corruption from noise.

Synchronization is key to the success of a distributed network. There are three significant levels to the M1000 DAQ synchronization:

1. The M1000 DAQ has a built-in GPS and precision master clock.

2. Within a single DAQ system, comprised of a M1000 DAQ and M1000 measurement nodes, the measurements are all synchronized to the master clock of the M1000 DAQ (sourced by either the GPS or precision on-board clock).

Sensors Used in Structural Monitoring

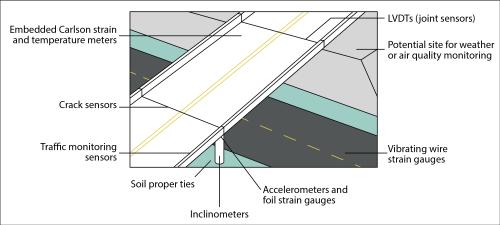

Because SmartSolo Scientific data loggers and M1000 DAQs are compatible with nearly every commercially available sensor, you can use the sensor that best meets your application. Typical sensors used for structural and seismic monitoring by our systems include:

Carlson strain meters

Vibrating-wire strain gages

Foil strain gages (set up in quarter-, half-, or full-bridge strain configurations)

Inclinometers

Crack and joint sensors

Tilt sensors

Piezoresistive accelerometers

Piezoelectric accelerometers

Capacitive accelerometers

Borehole accelerometers

Servo force balance accelerometers

Data Retrieval

Communication interfaces for retrieving, storing, and displaying data include direct connection to a PC or laptop, microSD cards, Ethernet, and several options for wireless communication.

Software

Our PC-based software options support connecting the M1000 measurement nodes directly to a PC or scheduling remote, automated data collection from the M1000 DAQ. Real-time monitoring and control simplify the entire data-acquisition process, while robust error-checking ensures data integrity. We can even help you post your data to the Internet.

Example Application: Monitoring an Overpass

SmartSolo’s monitoring systems are used for a variety of structural and seismic applications. Monitoring possibilities on an overpass could include: